PRPT-16 is testing equipment used in burn-in testing and the +Ruggedness Testing of LED Drivers and SMPS.

Keywords: Burn-In Testing, Ruggedness Testing, Voltage Dips & Interruption Test, IEC-61547/61000-4-5, Endurance Test, Continuous Run Test, Switching Cycle Test

Features :

- Heavy Duty Dual Relay Capable of Switching at Loads of more than 24 Amps.

- Automatic and programmable Switching

- 16 Channel Wattmeter/ Ammeter with settable limits (both High and Low)

.png)

Why is it required?

Normally user is expected to provide 230 Volts to a bulb/driver.

But it is specified to work from typically 130 V to 270V. Semiconductor-based equipment is tested at these extreme voltages and that too by switching at different voltages and OFF state.

To do this manually you need:

1- A Person or a Relay Switching as per requirement

2- Wattage Meter at each channel and a person to determine if it has gone out of limits.

PRPT-16 helps you automate this task by the easily customizable switcher and 16 channel wattmeter.

You only need to provide the power/Voltage as per your requirement and initial configuration.

Here is a typically required Ruggedness test –

Required Ruggedness Test for LED Drivers

|

Sr. No. |

Test |

Test Condition |

Instrument |

|

1 |

8 Hrs Continuous Run Test at Full Load |

At Nominal Voltage |

PRPT-16 |

|

2 |

8 Hrs Continuous Run Test at Full Load |

At minimum Operating Voltage |

PRPT-16 |

|

3 |

8 Hrs Continuous Run Test at Full Load |

At Maximum Operating Voltage |

PRPT-16 |

|

4 |

ON/OFF Test 1Hrs at Minimum Operating Voltage |

10 Sec ON and 5 Sec OFF |

PRPT-16 |

|

5 |

ON/OFF Test 2Hrs at Nominal Voltage |

10 Sec ON and 5 Sec OFF |

PRPT-16 |

|

6 |

ON/OFF Test 1Hrs at Maximum Operating Voltage |

10 Sec ON and 5 Sec OFF |

PRPT-16 |

|

7 |

High Voltage Run Test @320Vac |

30 MIN |

PRPT-16 |

|

8 |

High Voltage Run Test @350Vac |

30MIN |

PRPT-16 |

|

9 |

High Voltage Run Test @370Vac |

30MIN |

PRPT-16 |

|

10 |

High Voltage Run Test @400Vac |

10MIN |

PRPT-16 |

|

11 |

High Voltage Run Test @430Vac |

5MIN |

PRPT-16 |

|

12 |

High Voltage Run Test @440Vac |

4MIN |

PRPT-16 |

|

13 |

High Voltage ON/OFF Test @320Vac |

50 Times |

PRPT-16 |

|

14 |

High Voltage ON/OFF Test @350Vac |

50 Times |

PRPT-16 |

|

15 |

High Voltage ON/OFF Test @370Vac |

20 Times |

PRPT-16 |

|

16 |

High Voltage ON/OFF Test @400Vac |

20 Times |

PRPT-16 |

|

17 |

High Voltage ON/OFF Test @430Vac |

10 Times |

PRPT-16 |

|

18 |

High Voltage ON/OFF Test @440Vac |

5 Times |

PRPT-16 |

|

19 |

Square Wave Inverter Run Test |

1Hrs |

Other |

|

20 |

Square Wave Inverter ON/OFF Test |

10 Times |

Other |

|

21 |

Single Phase Generator Run Test |

1Hrs |

Other |

|

22 |

Single Phase Generator ON/OFF Test |

10 Times |

Other |

|

23 |

Oven Test @Nominal Voltage |

2Hrs |

Other |

|

24 |

Oven Test @Minimum Operating Voltage |

1Hrs |

Other |

|

25 |

Oven Test @Maximum Operating Voltage |

1Hrs |

Other |

|

26 |

Confirmation of Start-up Voltage |

50 Times |

Other |

|

27 |

Check Under Voltage Cut Off |

50 Times |

Other |

|

28 |

Check Under Voltage Cut-IN |

50 Times |

Other |

|

29 |

Check Over Voltage Cut-off |

50 Times |

Other |

|

30 |

Check Over Voltage Cut-IN |

50 Times |

Other |

|

31 |

Voltage Dips and Interruption Test (IEC-61547/61000-4-5) |

|

PRPT-16 |

You can download the above requirement as pdf here

Note: PRPT-16 can be used to perform most of the above-specified tests.

Test 19 to 30 have to be done manually through variac or through customized power sources.

These tests are required by most of the companies for R&D and Quality Testing.

You can download the Required Ruggedness Testing for LED Driver on below link –

The user can input two voltage sources. The switching of these voltages can be done using the rotatory switch.

Display –

It has an LCD display for showing individual loads of parameters, settings, and switching voltages.

LEDs indication

PRPT-16 has 16 set of green and red LEDs load pass/fail indication. If the load is connected to any channel related channel green LED will ON. If Load is failed than related red LED will ON. Load limits can be set using the Software interface for program mode or can be entered using buttons of PRPT-16.

Buttons

Three Buttons are given. UP/ DOWN are used for scrolling display and a set button is used to enter the setting.

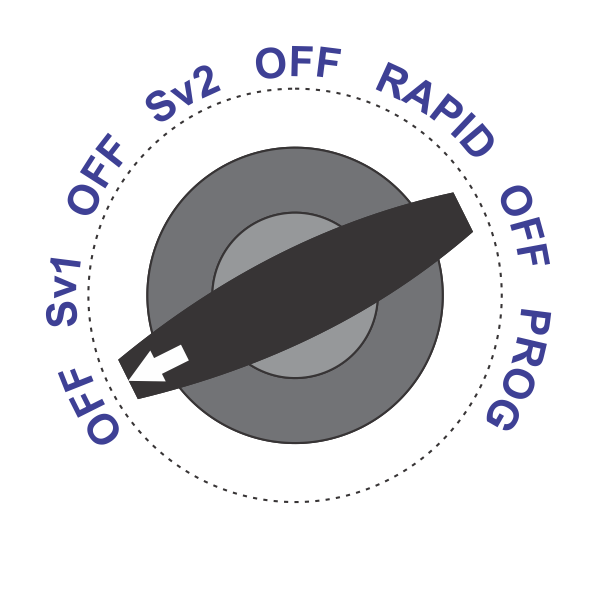

Rotatory Switch

Eight steps Rotatory switch is provided for easy navigations on testing. The OFF step is provided between two steps for safety purposes.

1- Prog – In this mode, voltage switching will be done as entered by the software.

2- Rapid – In this mode, switching will be done as set in PRPT-16 using buttons.

3- SV1- In this mode, only relay one will activate and a voltage source connected to this relay will apply.

4- SV2- In this mode, only real two will active and a voltage source connected to this relay will apply.

5- Off- No voltage at the output

Program Mode Feature –

PRPT-16 Saves the step as they completed. So if due to any reason meter goes off then it will start testing from step from where it goes OFF.

Eg. PRPT-16 goes off at step 6 now again when we start the PRPT-16 it will test from step 6 in program mode.

USB Port –

For Software interfacing.

Software –

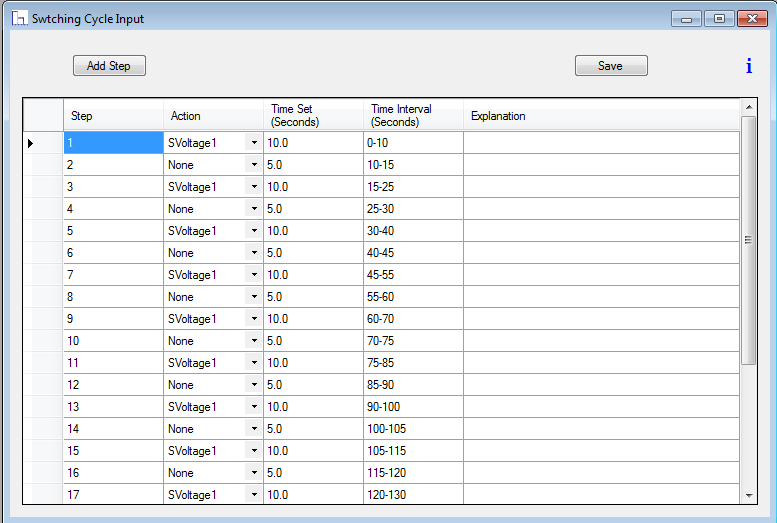

In Software You can set the required switching cycle.

For example, we have to do the 4th test given in the ruggedness testing requirement table.

So we have to do ON/OFF Testing for 1Hrs at minimum Operating Voltage. Switching Cycle is 10Sec ON and 5 Sec Off.

We have made this cycle in Software as below –

In the above software, image user can set the switching timings will relay operations. We have to ON/ OFF the

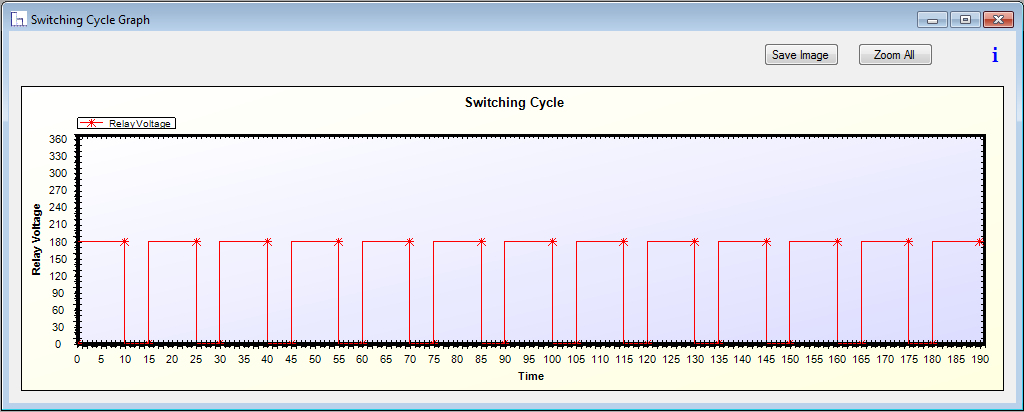

The switching cycle can be analyzed on the above graph.

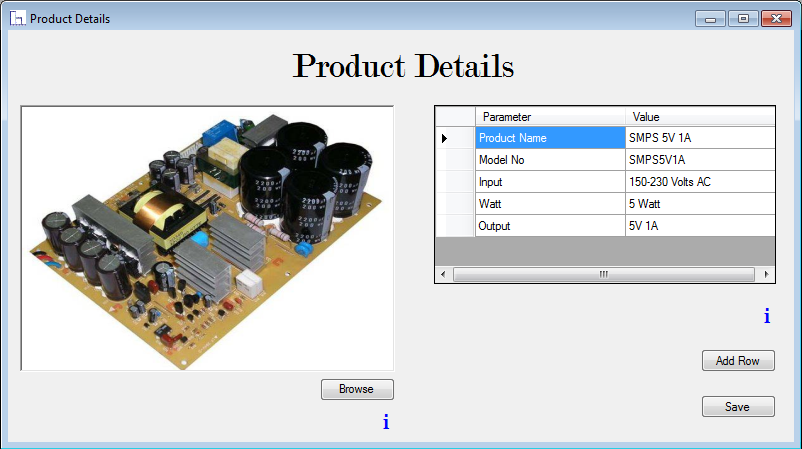

For reporting, we can add some information on the testing product as below –

We can also generate a pdf report based on the filled information in the software.

This data will transfer to PRPT-16 and can be run on prog mode.

1. PRPT16 Introduction with Production Testing

|

|

You can view the above video on YouTube at https://www.youtube.com/watch?v=iauSPF1HIfU This video contains most of the queries related to PRPT-16 like:-

|

Download PRPT-16 Catalog

Download PRPT-16 Catalog